Products

Orbit•NEC offers a fully integrated product design and manufacturing process that offers our customers the following benefits:

- Complete in-house manufacturing process including yarn preparation, compounding, weaving, calendaring rubber to fabric and the ability to provide specific rubber covers, when required.

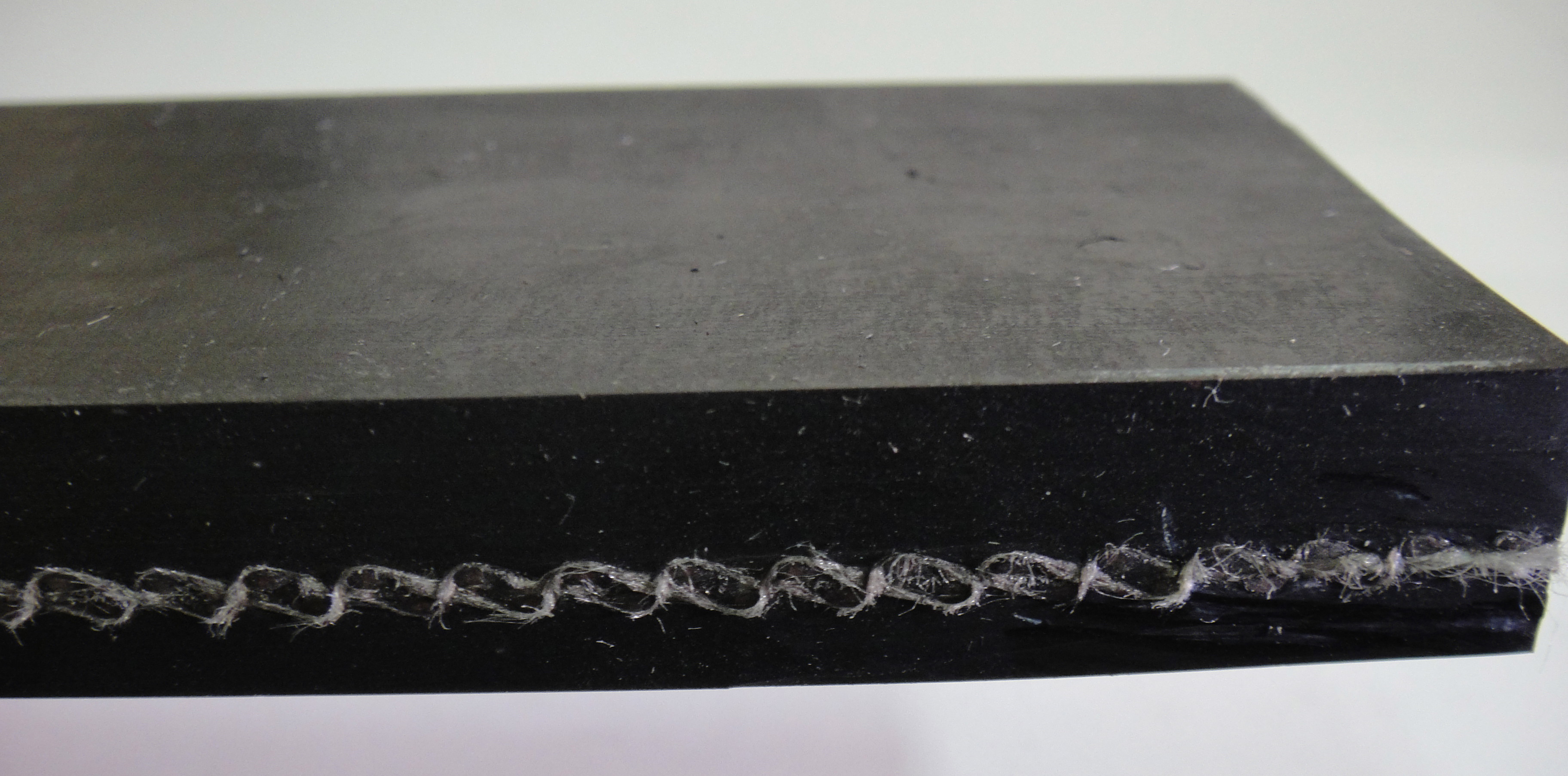

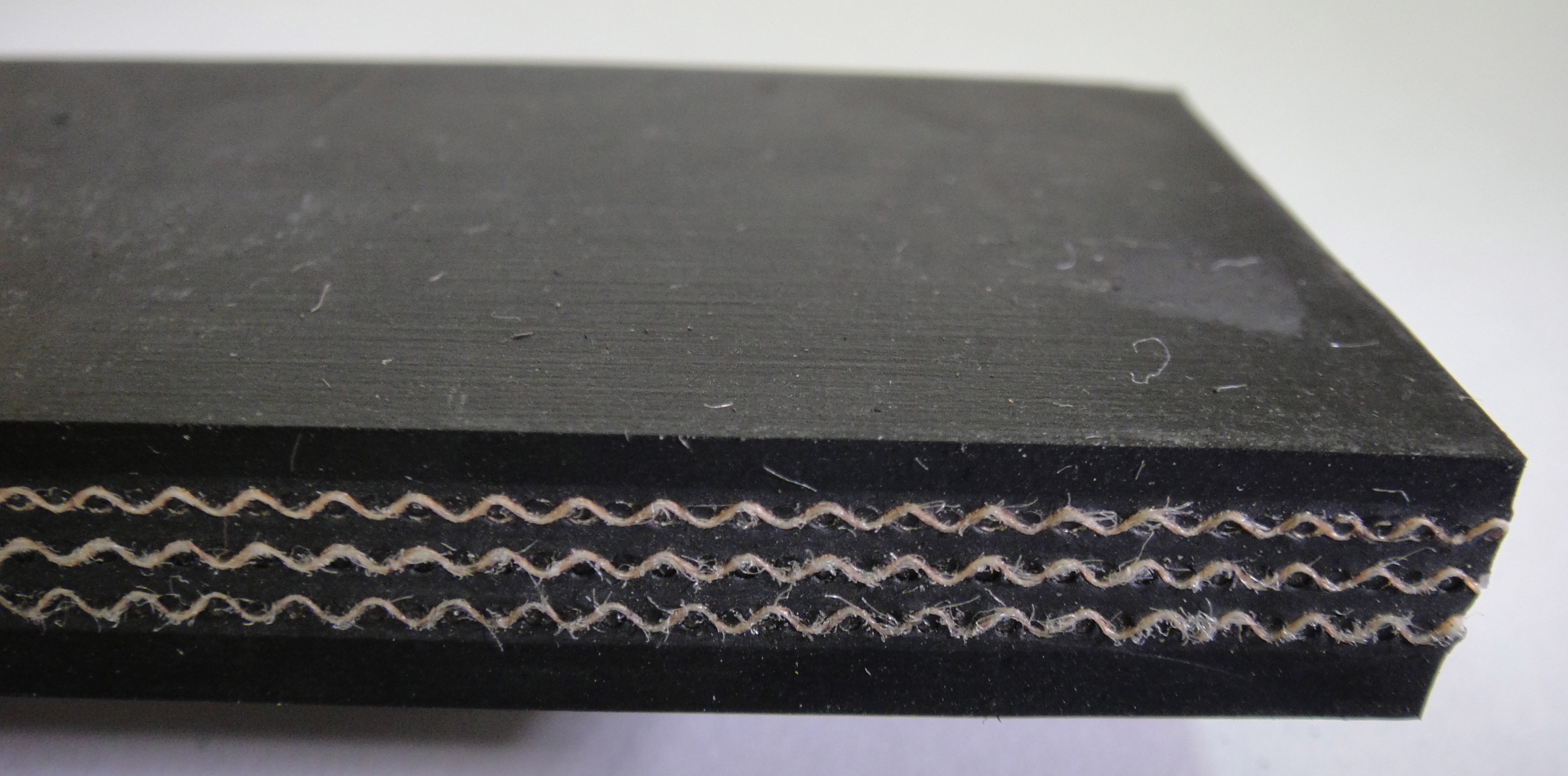

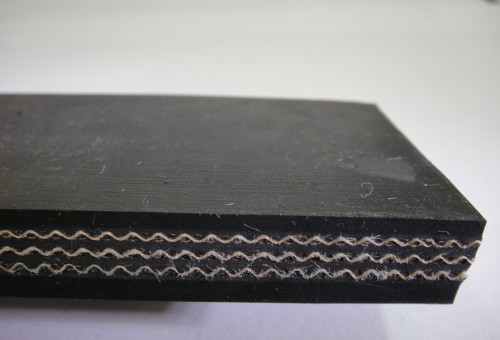

- A variety of woven fabric carcasses are designed to meet tensile strength requirements, operate efficiently and safely at rated working tensions. These belts also offer impact resistance, tear resistance, and excellent fastener retention.

- Specific rubber compound covers provide optimum protection of the fabric carcass, while the fabric provides excellent longitudinal strength and transverse flexibility whether the conveyor system is empty or fully loaded.

- Ability to manufacture heavier covers on a variety of woven carcasses that offer longer wear, and more tonnage over the life of the belt.

- Molded edge belt design is available to protect belt edges and resists edge fraying.

- Excellent belt tracking on long center conveyors as well as multiple transfer points, both loading and unloading.

- Each roll of belting is subjected to continuous in-process quality testing and must meet our stringent final quality standards, both physical properties and MSHA Part 14 requirements.

- Each belt is individually tested to pass the stringent standards set by MSHA.

- Products can be designed to conform to any country-specific standards for use in underground mines as well as surface applications where there is a potential for fire.

- Products can be spliced by mechanical fasteners or by splicing using hot vulcanizing methods

- Excellent for a wide variety of applications by choosing the proper compound and fabric to match the operating conditions of the individual conveyor system.

ORBITplast™

As the exclusive producer of ORBITplast™ a heavy duty solid woven PVC belting product specialized for bulk material handling in underground mining operations. It is available in 30″ to 72″ wide and type 3500 to type 12000. To order our finest solid woven PVC belt please contact +1 704-248-7748.

Product Range

- Width – 750 mm to 1830 mm (30” to 72”)

- Type – 3500 PIW to 15000 PIW (610 kN/m to 2625 kN/m)

- Covers – FRAS PVC (Up to 3.0 mm) and FRAS Rubber (Up to 10.0 mm)

- Special Covers – On offer for abrasion, heat and oil resistance

- Roll Length – As required by customer subject to shipment restrictions by road and sea

- Colour – Black. However, special coloured PVC covers can be made on request

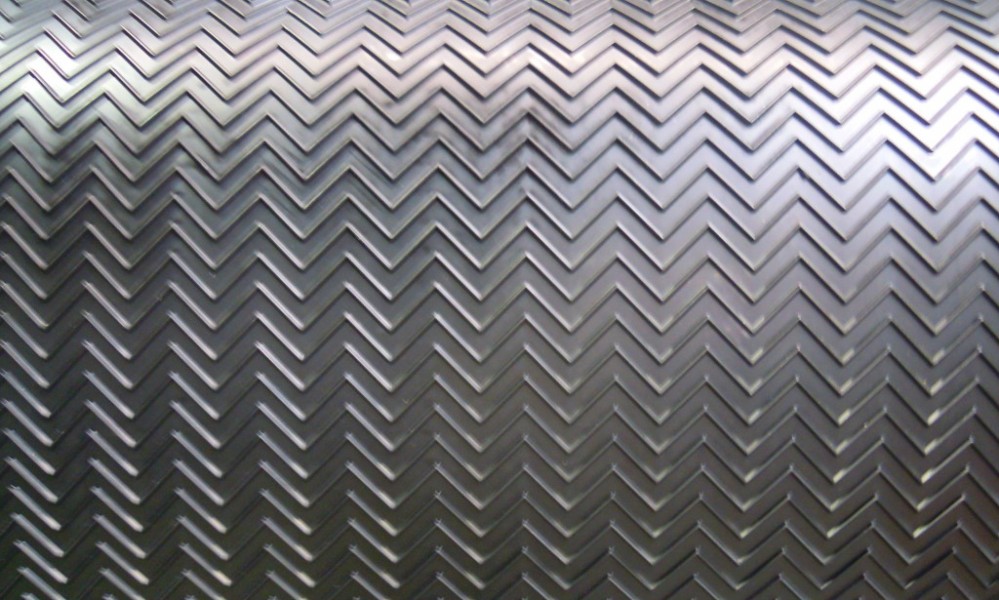

- Silent weave construction

While USA and Canada continue to use imperial units, other countries have changed over to metric units. South Africa uses the word ‘Class’ for belt designations while many other countries use the word ‘Type’. We at Orbit respect each country’s unique way of expression and service as per their requirements.

While the standard product range is after considering years of usage pattern in various countries, non-standard tailor made products can also be designed and manufactured on special request and mutual agreements.

Our unique in-house R & D facility helps in catering to every customer need to the best of our ability.

Orbit applies factor of safety of 10 (10:1) while designing and manufacturing any solid woven belt as a standard practice. However, we can consider, on user request, any special application requirement where the factor of safety is required to be changed.

Orbit designs, manufactures and supplies conveyor belts considering the users to be adhering to the installation, operating and maintenance practices as are commonly and widely known. However, we can provide such details on request.

Physical characteristics of the standard products thickness and weight, as in the following table, are nominal values and can change due to continuous R & D efforts or specific customer need. Buyers are advised to get the offered values reconfirmed before placing any orders.

Nylon (NN) Product Range:

| Item | NN135 | NN160 | NN200 | NN250 | NN300 | NN350 | NN400 | NN500 | |

|---|---|---|---|---|---|---|---|---|---|

| Min Tensile Strength | kg/cm-ply | 135 | 160 | 200 | 250 | 300 | 350 | 400 | 500 |

| lb./in-ply | 770 | 914 | 1142 | 1428 | 1713 | 2000 | 2284 | 2855 | |

| Working Tension Rating (Vulcanized) | kg/cm-ply | 13.5 | 16 | 20 | 25 | 30 | 35 | 40 | 50 |

| lb./in-ply | 77 | 91 | 114 | 143 | 171 | 200 | 228 | 286 | |

| Approx. Gauge/Ply with skim-coat | mm | 0.85 | 0.90 | 1.15 | 1.20 | 1.35 | 1.60 | 1.70 | 2.10 |

| in | 0.034 | 0.035 | 0.045 | 0.047 | 0.053 | 0.063 | 0.067 | 0.083 |

Special Features:

- Exceptional impact resistance to the carrying surface.

- Superior fastener holding ability.

- Excellent troughability and flexibility.

- Smaller pulley requirements.

- Great resistance to water and mildew.

Polyester (EP) Product Range:

| Item | EP125 | EP160 | EP200 | EP250 | EP300 | EP350 | EP400 | EP500 | |

|---|---|---|---|---|---|---|---|---|---|

| Min Tensile Strength | kg/cm-ply | 125 | 160 | 200 | 250 | 300 | 350 | 400 | 500 |

| lb./in-ply | 714 | 914 | 1142 | 1428 | 1713 | 2000 | 2284 | 2855 | |

| Working Tension Rating (Vulcanized) | kg/cm-ply | 12.5 | 16 | 20 | 25 | 30 | 35 | 40 | 50 |

| lb./in-ply | 71 | 91 | 114 | 143 | 171 | 200 | 228 | 286 | |

| Approx. Gauge/Ply with skim-coat | mm | 0.09 | 1.00 | 1.20 | 1.30 | 1.50 | 1.70 | 2.20 | 2.80 |

| in | 0.035 | 0.039 | 0.047 | 0.051 | 0.059 | 0.067 | 0.087 | 0.110 |

Special Features:

- High resistance to tension.

- Low elongation.

- Outstanding dimensional stability.

- Impact resistant.

- Complete resistance to moisture and mildew.