Quality Assurance

Concern for quality and strict adherence to in-process checks and controls are the keys of a good product. ORBIT PLAST products undergo a strict quality check in its well-equipped laboratories and on shop-floors, from incoming raw material to in-process to finished products.

- Incoming raw material – yarns and chemicals – are tested on arrival as per the norms agreed between supplier and purchaser.

Every finished roll is tested of its conformity to physical and FRAS test requirements of every user country and as agreed between purchaser and Orbit.

- Physical properties include width, thickness (belt & covers), tensile strength (warp & weft), elongation (warp & weft), adhesion (cover to carcass and internal), fastener retention (static & dynamic), cover abrasion, troughability, etc.

- FRAS tests include flame (finger burn), flame propagation (Mid-scale/B.E.L.T), drum friction and antistatic (static conductivity)

- Abrasion Testing

- Anti-Static Testing

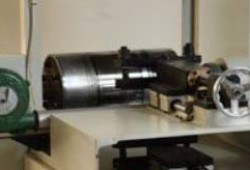

- Drum Friction Testing

- Flame Testing

- Tunnel Testing

- Tensile Testing